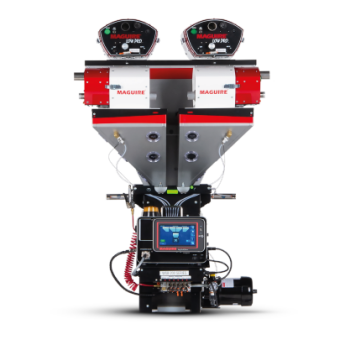

The Maguire LPD Vacuum dryer operates with 3 stainless steel canisters, mounted on a carousel that indexes step by step through the drying process.

Step 1 – Heating Phase

- The canister is filled with raw material.

- Material is heated from ambient to the required drying temperature.

- The time to get the material up to temperature is rapid - typically 20 - 30 minutes for most materials.

Step 2 – Vacuum Drying

- The canister indexes from the HEAT stage in (Position 1) to VACUUM stage in (Position 2).

- The vacuum canister is sealed and a high vacuum is applied to the hot material, dropping the boiling point of moisture to 133°F / 56°C.

- Vacuum is 56"Hg / 700 mmHg, typically for 20 to 30 minutes, depending on the material, initial / target moisture and required throughput.

- Vacuum only active usually 1-2 mins per cycle - minimal energy.

Step 3 – Material Feeding

- Material is now ready to use in production.

- The canister indexes to MATERIAL TAKE OFF (Position 3).

- A valve in the canister activates to allow material to feed to the material take off.

- Any material left in the canister by the end of the drying cycle time simply rotates back to HEAT stage, (Position 1) and fresh material supplied from the VACUUM stage (Position 2), eliminating any chance of moisture re-absorption or material cooling.

How a Low Energy LPD Dryer works: